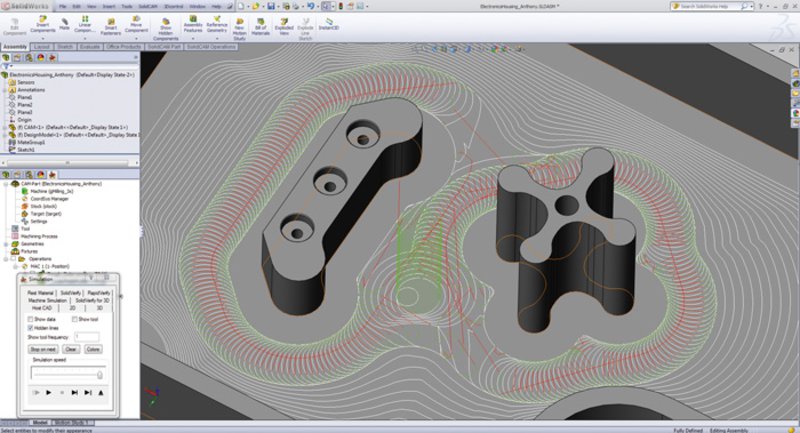

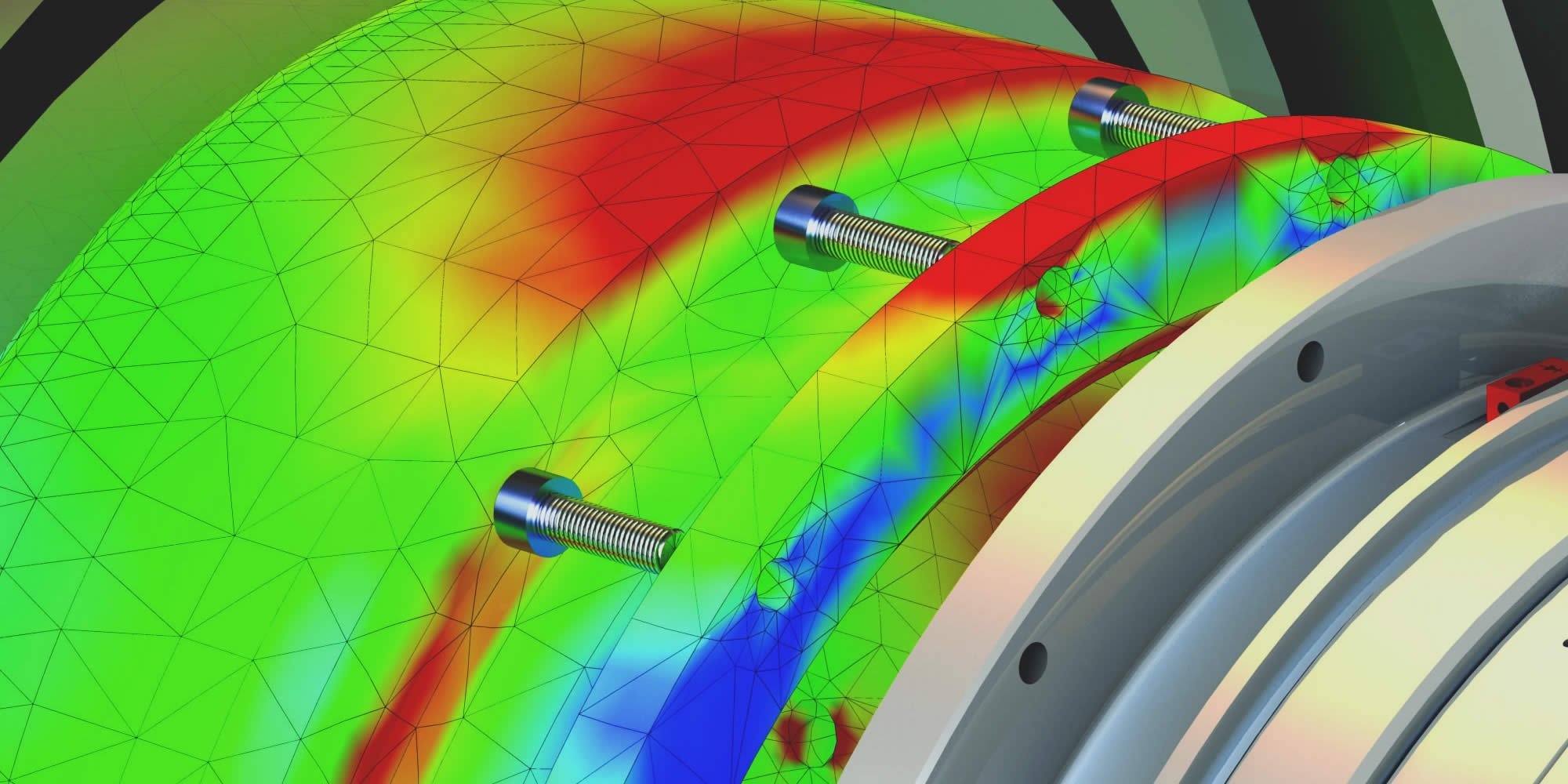

SolidCAM is fully integrated inside SolidWorks and allows Dixons Surgical to make just one machining program and use the CAD system's parametric tables to produce the other variants. Our two main criteria for a CAM system –seamless integration in SolidWorks and the ability to program our Mazak Quick Turn Nexus - eliminated every system we looked at, except SolidCAM." The parametric tools inside SolidWorks allow us to model just one part of a family of parts and, with a parametric table, automatically create the multiple versions, common in our industry. Jay Dixon continues, "We rapidly appreciated the benefits of 3D CAD for both new and existing parts. During 2010 we started to get requests for parts which were difficult to program on the machine, especially the mill-turn, and which were already modelled in 3D, so we started to look for a suitable CAM system."ĭixon Surgical had already invested in SolidWorks from Cadtek Systems Ltd, so it was looking for a package which would integrate with it and which would also be able to program its mill-turn machines. Now we have standardised on Mazak machines, including a Quick Turn Nexus 200 MSY, which has milling, Y-axis and sub spindle, and a VCN 410A vertical machining centre. Programming was either manual or on-machine conversational. Jay Dixon, Managing Director says, "We have been using CNC machining since the early ‘90s. These changes encouraged the company to invest in both SolidWorks and SolidCAM, including its revolutionary iMachining module. As the market has matured, Dixon Surgical has now progressed to making more complex orthopedic instruments, modelled in CAD.

Since 1948, Dixons Surgical in Wickford, Essex has been manufacturing re-useable surgical instruments.

0 kommentar(er)

0 kommentar(er)